General Safety Information (KRC Safety)

Safety Precautions

Before using or entering the CARBON palletizing cell, it is important to understand it’s safety features, and how to safely use and maintain the system. Unless this system specifically is using a Human Machine Collaboration (HRC) system via KUKA.SafeOperation, always lockout control power before entering the palletizing cell, and follow all of your company’s safety procedures regarding automation. It is the responsibility of each person using the palletizing cell to understand the safety features and limitations before use. If you are unsure how to complete a given task safely, please seek further information and/or training.

Safety Circuit

Safety is provided by the KRC4 robot controller Safety Interface Board (SIB), which is a dual channel, cross talk monitored safety device that ensures that the system is safe, and that the safety circuit is functioning at all times. Any safety violation will stop and apply brakes to the robot servos, and drop all control voltage to all devices in the cell. The gripper may retain control voltage if it is deemed necessary to safely grip the product.

If operation is stopped by a safety device, and clearing said safety devices cannot be done without jogging a conveyor or the robot, the safety circuit may be bypassed with a key switch and an enabling switch (often known as a dead man’s switch). If this is required, consult your company’s policy on the matter.

Safety Devices

⦁Gate Switches

Many CARBON Palletizing cells are provided with one or more access gates. We utilize Fortress safety hardware in these situations that contain rotary actuated gate switch and handle, a twist reset emergency stop button, as well as a “pause request” button. Either rotating the handle, or pressing the e-stop button will immediately stop the robot and conveyors. If it is not an emergency, the preferred method is to request entry via the pause button, and wait for the robot to pause (not covered here).

⦁Light Curtains

Anywhere pallet loads are entering or exiting the cell, light curtains will be installed in order to protect unintended entry into the cell. FOCUS uses Keyence GL-R light curtains with full length indicator lights. Anything to break the plane of the light curtain larger than 1 inch will e-stop the cell. For this reason, it is important not to accidentally wave anything through the light curtains. Keep your hands close to your body when near the light curtains to avoid accidental e-stops.

⦁Muting Light Curtains

In the case that a full pallet must travel through a light curtain without stopping the system (full load discharge for example), The light curtain will be configured to mute during this time. 2 signals will start the muting. The first signal comes from the system transferring a pallet out of the cell. The second signal is provided by a photo eye inside of the cell. When both signals are met, the light curtain will remain muted until either both signals are dropped, or one signal is dropped and the load has cleared the light curtain. Once one of the signals is dropped (typically the photo eye) the light curtain will allow a maximum of 4 seconds for the pallet to exit the cell before unmuting.

⦁Light curtain Indicators

The lights along the face of the light curtains have 5 states:

⦁ Off – Either powered off or very poorly aligned

⦁ Flashing Red – Faulted

⦁ Solid Red – Either violated or slightly misaligned

⦁ Flashing Green – Muted (in some installations indicates ready to reset)

⦁ Solid Green – Safe and clear

Safety Software

Any time safety is violated, or a fault in the safety circuit is detected, the system will e-stop, removing control power from the system, as well as stopping and applying brakes to the servos. The safety condition must then be resolved, acknowledged, and drives and control power reset.

In addition to the standard safety circuit and controls, CARBON palletizing systems utilize KUKA.SafeOperation software and hardware. This combination allows for reduced cell size by creating safety rated spaces for the robot to operate, and in some instances allow for interaction in the cell by operators while the robot continues working using HRC principals and standards. In order to provide these controls, the robot will periodically test that its brakes are performing within normal limits, and that its positional data is accurate by measuring itself against a sensor at a known location. These tests are run any time the cell is powered down, and at pre-defined timed intervals.

Locking Out Power

⦁Control Power

Locking out control voltage is done at any of the lockable e-stops. Typically, this is at one of the gates. When the gate handle is open, a lock hasp is presented in order apply a lock. While the gate is unable to latch, the system cannot provide output power to the robot or conveyors without bypassing the safety circuit.

⦁High Voltage

There are generally 2 places to lockout high voltage power a CARBON palletizing cell. One location is on the KRC4 robot controller via the rotary disconnect (section 2.). The other is the conveyor power disconnect, which is a flanged disconnect on a fuse box or a panel door. The system layout will call out where these points are.

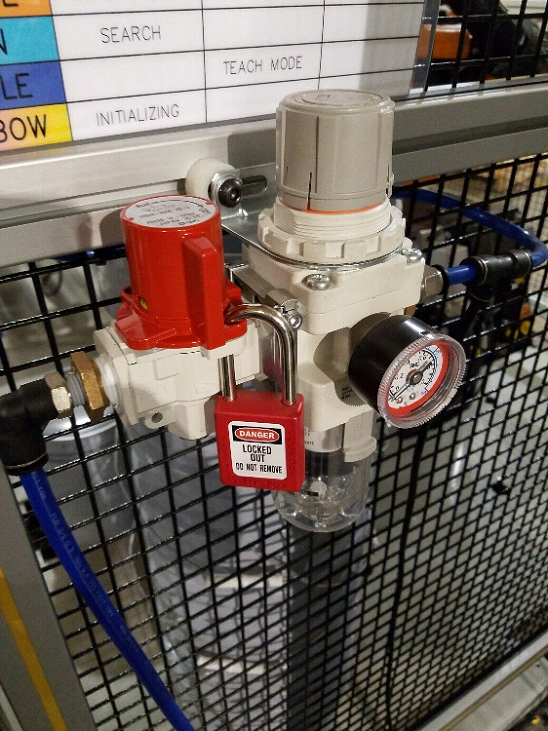

⦁Air

CARBON palletizing cells are shipped with a system air dump mounted to an air filter/regulator unit. This air dump will drop all air pressure from air lines prior to valves, and provides a point to lock out the dump valve. Keep in mind that this only dumps air in the supply lines. Some cylinders may have closed center valves that keep air pressure in the cylinder when powered down. This is done to keep certain items from moving in an e-stopped condition, but presents a safety consideration when working on these cylinders. Use the manual overrides on the valves in order to vent the cylinders if needed.